Modal analysis is a vital technique in structural dynamics used to identify a structure’s natural frequencies, mode shapes, and damping characteristics, thereby providing insights into its dynamic behavior under different loading conditions. Medha SMH Rail, after developing new monorail vehicles for the Mumbai Monorail, aimed to study the modal responses of the structural beam during operation. A Finite Element Model (FEM) of the beam had already been developed, and experimental modal analysis was undertaken by NV Dynamics to correlate the FEM results.

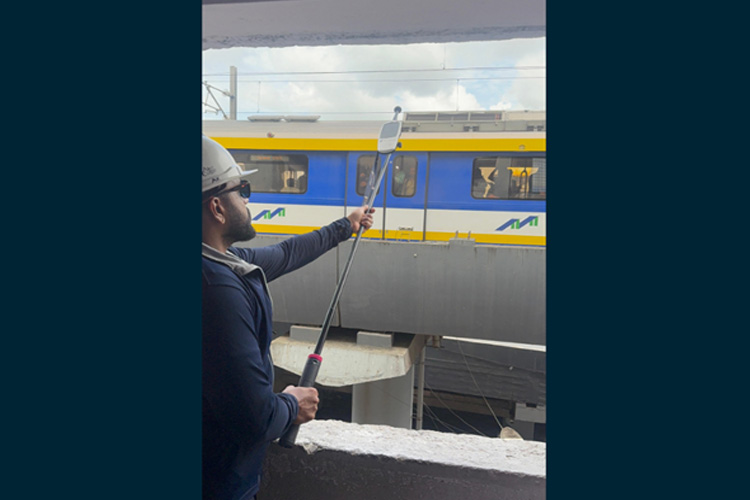

Larsen & Toubro Limited (Construction) engaged NV Dynamics to conduct detailed noise and vibration assessments for the proposed Mumbai Metro Line-4, extending approximately 19.48 km between Bhakti Park Metro Buffer End and Mulund Fire Station, with 17 elevated stations on a standard gauge double-track alignment.

NV Dynamics was engaged by Goodrich Aerospace Services Pvt. Ltd. to install acoustic insulation solutions and to conduct noise validation measurements for their vibration shaker room facility.

Udupi Cochin Shipyard Limited (UCSL) is a wholly owned subsidiary of Cochin Shipyard Limited (CSL). Previously known as Tebma Shipyards Limited, UCSL was acquired by CSL in 2020 and became operational in 2021. UCSL specializes in shipbuilding, including high bollard pull tugs and general cargo vessels.

NV Dynamics was retained by Afcons Infrastructure Limited, to assess vibration severity levels due to the ongoing metro construction activity along the 11.2 km metro corridor of Kochi Metro’s Phase 2.