NVH is a sub-set of the larger physics that all systems work-by, we dive-in at the design & development stage of a concept or in post-production scenario; it doesn’t matter either way, we make a head-start.

We draw up a plan for our customer who can walk through the entire process of consulting; the task is defined in totality such that there are less or no ambiguity on what is the take away, 30% of all our consulting task is spent on initial discussions, documentation and defining the scope that meets the customer requirement.

We are a compact & organised team, quick and concise, our usual turn-around time to respond to customer with initial reply is under 6 hours.

Quality consulting is an integrated approach and we combine the best of class NVH tools, professionals with domain specific knowledge and to top it all, the eagerness to learn as we serve, NV Dynamics is your extended Facility.

Let’s not be lost, NVH data acquisition and processing is not analysis or interpretation; at max, it’s much to do with good data and its correct acquisition. We recommend that you do both and later add all your understanding of the product and process you test, by using the right NVH tools in tune with the problem. Further and most importantly, never generalise, as no two problems are similar.

Our N&V Testing and Analysis are a holistic package; begins with a clear and complete listing to customer definition of the problem, moves on to deploying the right tools and resources, work on a single focus to mitigate, whatever it takes. While our suite of tools provide means to address much of NVH issues, the real value is our engineering team who make the difference to what we test, analyse and solve.

Structural dynamic parameters to be understood in its elements require Experimental Modal Testing as the method; our expertise in conducting full size modal testing, beginning from creating geometry, running both impact or shaker based Modal testing on large count nodes to deriving Modal Parameters using industry standard MODAL suite and finally run MODAL validation are a complete package.

The Modal parameters thus derived are used in MODAL modifications, Design updating and co-relating with FE models.

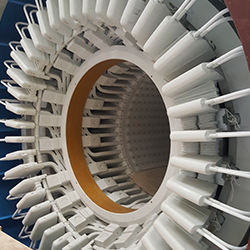

Variable speed rotating equipment, gear box and multi-stage drives, most require high quality adaptive sampling techniques for vibration analysis; with refined and improved instrumentation with powerful software tools, we provide comprehensive test solutions for most of rotating equipment analysis.

High slew rate, high RPM rotating equipment are challenge to handle and NV Dynamics has run some of the crucial turbine order tracking exercises effectively.

Acoustically treating buildings, inside out – working both at design stage and at a post construction scenario with methods and implementation plans that are standardised by practice. We use Sound Plan and other professional assessment and modelling tools to achieve prescribed acoustic parameters on case to case basis

Working in tandem with structural engineers and interior designers, we bring up plans to optimise the acoustical treatment and integrate design as much with the aesthetics of the space considered.

We bring in our expertise of Engineering services converge to specialised solutions; we work on one-off product development for Noise & Vibration applications using case specific hardware and proprietary software tools and deliver customised solutions for complex testing and benchmarking requirements. The integration further goes to including multiple measurement parameters such as force, pressure, temperature and much more.