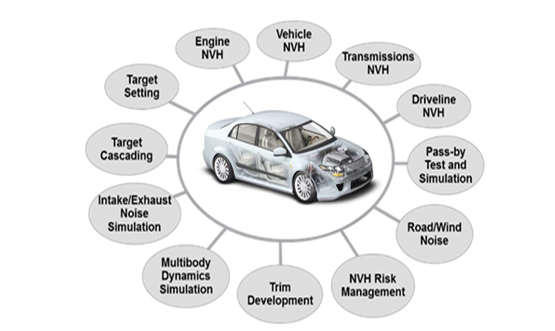

Noise, Vibration and Harshness plays a key role in automotive engineering; the use of N&V tools is all through the development and manufacturing process.

The requirement of superior quality noise and vibration parameters are governed by two factors; firstly, to meet regulatory requirements and secondly to have improved customer experience. While the efforts to achieve both these goals go hand in hand, there are specific sub-systems in an automobile that are considered for addressing the noise and vibration issues.

- Engine is a significant source of noise and vibration inside the vehicle. Engineers use various techniques to reduce engine noise and vibration, such as using sound-absorbing materials in the engine compartment, designing the engine to reduce internal noise sources, and using active noise and vibration control systems.

- Transmission and drivetrain are another significant source of noise and vibration in a vehicle. Designers use various techniques such as using damping materials in the transmission housing, optimising gear design and alignment, and using active control strategies to reduce transmission noise and vibration.

- Road types can also be a source of noise and vibration inside the vehicle. The approach here is designing the suspension system to reduce the transmission of road noise and vibration to the vehicle body, using sound-absorbing materials in the vehicle interior and using active control strategies to reduce road noise and vibration.

- Wind and aerodynamic noise are yet another source of noise and vibration inside the vehicle. This is usually addressed by designing the vehicle body to reduce aerodynamic drag, working on the seal design between the door and the body to reduce wind noise and many such ideas that minimize the air interaction on the body.

- In addition to the above, automotive engineers can also use various testing methods to evaluate/fine tune the noise and vibration performance of a vehicle, such as modal analysis, random vibration testing, and durability testing. Each of these testing is intended to achieve optimal noise and vibration performance and as well helping the overall operational performance of the vehicle.

Over several decades now, the efforts to improve on the noise and vibrations performance of the automotive are on and continued efforts are put in place using latest technologies, materials and innovative design approach. With the electric vehicle revolution on the horizon, noise and vibration parameters will become even more important given that the EVs are relatively silent by their composition.

NV Dynamics is actively involved in many layers of automotive testing and validation for over 15 years now, going with the changing times, we are developing multiple testing modules that help startups and other automotive industries to implement upfront design considerations that help achieve noise and vibration targets. For more information on our services, visit our website NV Dynamics or get in touch with us at services@nvdynamics.com.